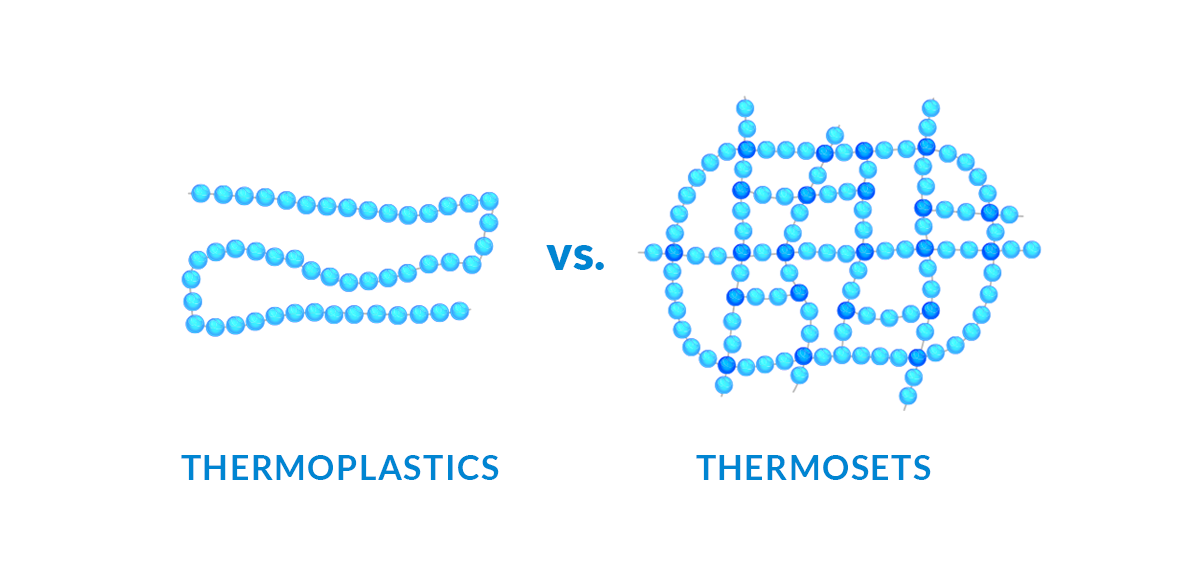

All plastic materials fall into one of two categories: thermosetting polymers, which remain solid and retain their shapes under heat once they’ve been cured and thermoplastic polymers, which deform and even melt under heat after curing. At times, customers come to us to ask which polymer technology is best suited for their design and application. Here is a checklist of engineering trade-offs we discuss with them when making those decisions.

In addition to being heat-, corrosion-, and water-resistant, thermosets have high dielectric strength and a high strength-to-weight ratio. The first thermoset, polyoxybenzylmethylenglycolanhydride, which is better known as Bakelite, was developed by the Belgian chemist Leo Baekeland in Yonkers, New York, in 1907. Bakelite’s ability to maintain its shape under high heat, coupled with the fact that it was available in a range of colors, made it popular for a variety of applications, including handles on cookware, radio, and telephone casings, and electrical insulators.

Determining when the first thermoplastic came into practical usage is a little trickier. Some sources say polyvinyl chloride (PVC), which was accidentally discovered in 1838 and again in 1872, didn’t find real-world applications until the mid-1920s. Others point to celluloid’s development, which initially was invented in 1848. And there are those who would opt for polystyrene, which was accidentally discovered in 1839, but which wasn’t manufactured commercially until the early 1930s.

These days, thermoplastics are considered to be the “pretty” members of the polymer family, appearing in products such as the shiny plexiglass displays found in shopping malls. By comparison, thermosets are typical to be found in “out of sight and out of mind” electrical and construction applications, such as the insulators at the top of cell towers, for example.

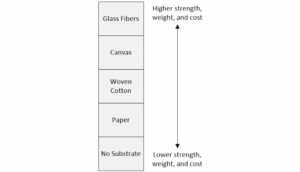

There is a wide variety of thermoset materials available, including GPO I, II, III, IV, paper-based phenolics, canvas-grade phenolics, FR-4, G7, G10..the list goes on. In most thermoset products, these materials are used in conjunction with a substrate or base material, such as paper, woven cotton cloth, canvas, and glass fibers to achieve the desired properties for the target application. You can picture it this way:

Of course, the above diagram offers only a simplistic view of things. Each of the substrate materials are available in many different forms, such as the number and size of their fibers, for example. Also, the combination of different thermoset materials with different substrate materials offers a multi-dimensional solution space regarding characteristics such as mechanical properties, dimensional stability, resistance to chemicals, resistance to heat, resistance to moisture, flame retardance, insulating properties, and dielectric properties.

A checklist of properties and questions to ask might include:

- Is this an electrical application?

- Is there moisture in your environment? Is there salt or humidity, perhaps if you’re in Florida?

- What’s the working operating temperature?

- How important is structural integrity to the part you’re designing? Does it have to hold something?

- Do we have to paint it after production?

- What’s the flame rating or flammability you’ll encounter?

As with nearly any engineering decision, the material required will call for a blend of performance trade-offs. Stronger materials may provide the durability you want, but they come with cost or weight disadvantages to your application.

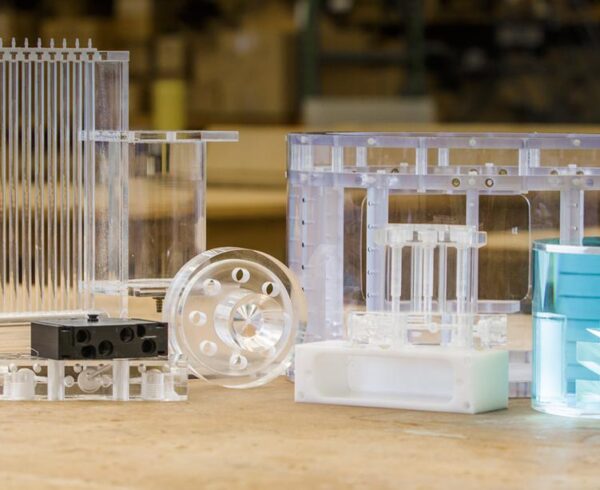

Here at HP Manufacturing, we’ve been working with both thermosets and thermoplastics since our company was founded in 1939. In the case of thermoplastics, we have tremendous expertise with respect to machining, polishing, and painting parts and creating sub-assemblies – in effect everything that’s required to satisfy our customers’ exacting requirements. Working with thermoplastics is not a trivial matter, because different materials exhibit widely different characteristics that require specialist tooling and specific “speeds and feeds.” This explains why our decades of expertise in this area allows us to create the most complex parts while maintaining the tightest tolerances.

If you are interested in learning more about this topic, including help with deciding which combination of thermoset and substrate materials will best satisfy the requirements of your unique application, then contact us for a consultation at 216-361-6500 or info@hpmanufacturing.com.