When it comes to working with plastics, shaping and forming processes such as cutting and milling can certainly seem routine. Yet the expertise of your precision machining partner can mean the difference between hitting your tolerances or delivering products out of spec.

Dating from the 1630s when it was used as an adjective, the English word “plastic” comes from the Latin “plasticus,” which itself comes from the Greek “plastikos,” meaning “capable of being shaped or molded into various forms.”

Since the early 1900s, the words “plastic” and “plastics” have also been used as nouns embracing a wide range of synthetic or semi-synthetic materials that use polymers as their main ingredient. Plastics typically fall into one of two categories: thermoplastics, which deform and even melt under heat after curing, and thermosets, which remain solid and retain their shape under heat once they’ve been cured.

Forming

Plastics are often presented in a variety of off-the-shelf stock shapes and sizes, in which case they will almost invariably have to be formed in some way into a new shape before use, via molding and extruding. Forming plastics isn’t much different than metal forming processes, where heat and pressure are used to aid in the process.

Machining

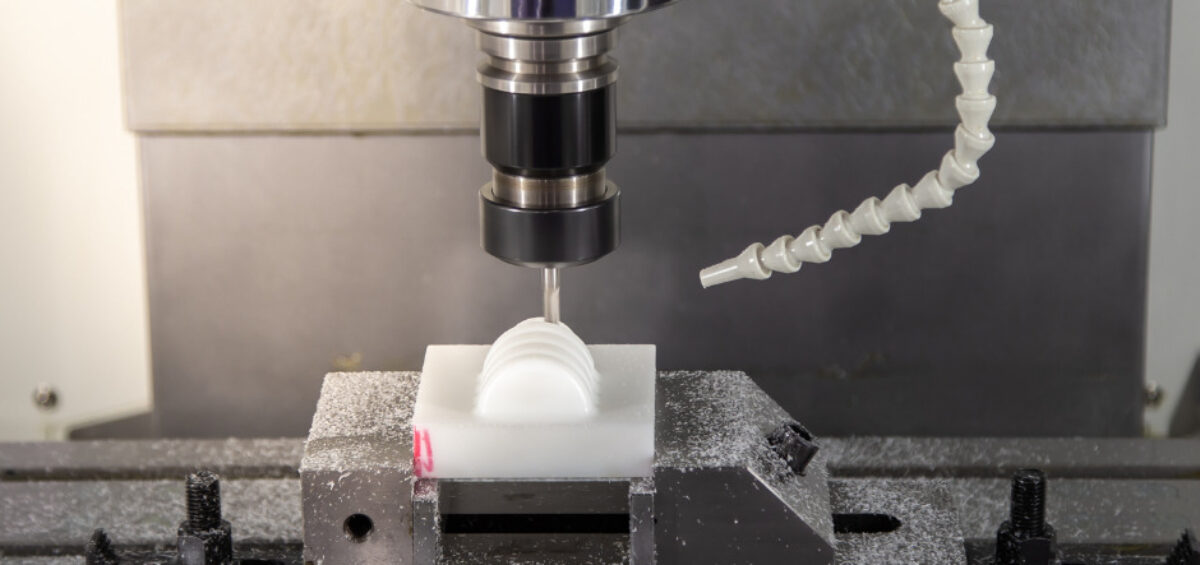

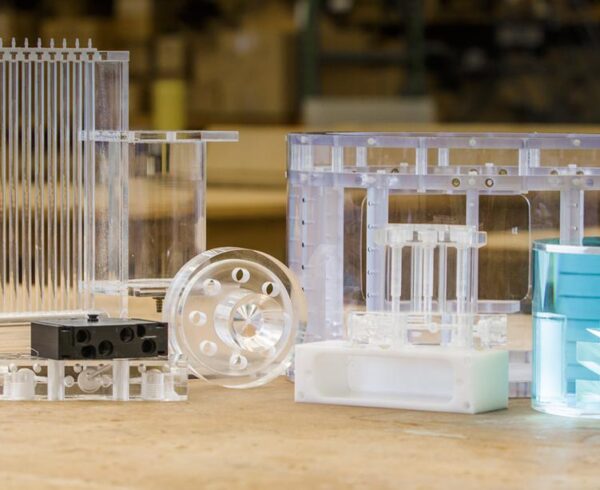

In some cases, forming/molding isn’t sufficient to create the necessary shape or structure to your plastic component, so machining is required to provide enhanced dimensional accuracy and precision.

The term “machining” refers to using subtractive manufacturing techniques to produce parts and products created using a wide range of materials (metals, plastics, ceramics, etc.). Each type of material has its own characteristics and unique machining requirements. In the not-so-distant-past, machining operations were performed using unintelligent tools like lathes, mills, and drills that were controlled by hand using devices such as wheels or levers. Today, machining operations are commonly performed using computer numerical control (CNC) machines, which offer tighter tolerances and higher levels of accuracy and repeatability.

CNC machines are available with a range of capabilities. In many cases, the workpiece remains fixed while the tool moves along or around one or more axes. A 2-axis machine means that the tool can move along the X-axis (horizontal) and Y-axis (vertical). A 3-axis machine adds the ability to move along the Z-axis (depth). In the case of a 4-axis machine, the inclusion of the so-called A-axis means that workpiece itself can be rotated around the X axis. Similarly, in the case of a 5-axis machine, the so-called B-axis means that workpiece can be rotated around the Y axis. This means that 4- and 5-axis CNC machines can be used to fabricate sophisticated structures that cannot be realized using 3-axis machines.

There are eight common machining techniques used in precision plastics:

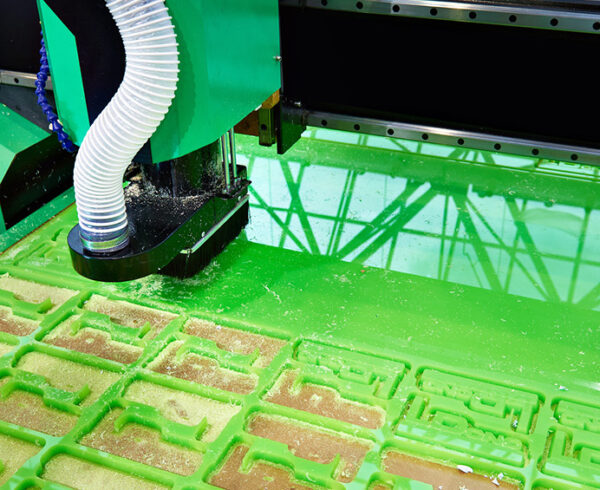

Cutting: May be performed using band saws, panel saws, saber saws, table saws, laser cutters, milling machines, and routing machines.

Turning: Workpieces are cut while they are being rotated. CNC machines generally employ two axes for this task (X and Y), but newer models have more axes, allowing for more advanced jobs to be machined.

Routing: Similar to milling, but routers typically operate at higher speeds with less precision. Routing may be used to cut or shape the workpiece. It’s often used to provide complex profiles on the edges of flat workpieces.

Milling: Though similar to routing, mills typically operate at lower speeds with higher torque and higher precision. This can be used to cut and shape, with functions that include face milling, shoulder milling, tapping, and drilling.

Drilling: Drilling typically utilizes a rotating cutting tool to produce round holes in a stationary workpiece, but multi-axis CNC machines may allow the workpiece to be rotated between drilling operations.

Grinding: This is used to achieve tight tolerances and create good surface finishes. In some cases, the grinding surface remains stationary while the workpiece is rotated. In other cases, the workpiece is held steady while a rotating grinding wheel is used to remove material.

Finishing

Following machining, various processes may be used to further modify the plastic part or product. Most of the time, the term “finishing” is taken to mean altering the surface of the workpiece to remove any scaling, pitting, or marks created during the machining processes. However, it may also include treating the entirety of the workpiece as in the case of annealing.

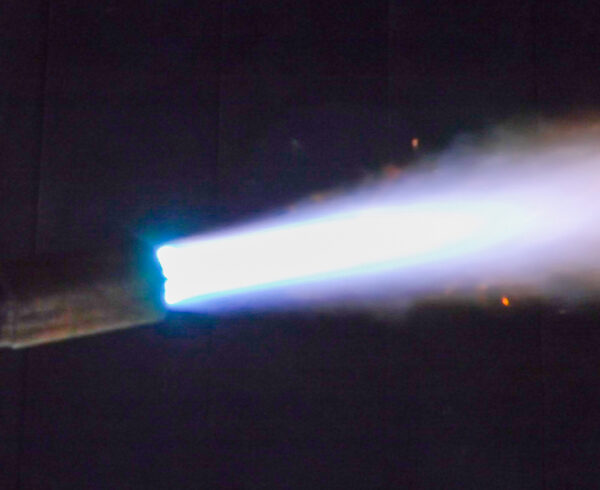

Annealing: This refers to heating or baking the workpiece to relax any internal stresses that may have been caused by uneven heating and cooling during the machining processes.

Polishing: Plastics may be polished using special compounds containing wax or a fine abrasive. In addition to enhancing the appearance of the workpiece, polishing may be used as a precursor to coating.

Coating: This is typically the final step in the process, which involves adding one or more layers of material (such as paint) to enhance the aesthetics and/or provide environmental protection.

Potential Problems

Since thermoplastics are significantly lower in hardness as compared to their thermoset counterparts, they can be machined using higher cutting speeds and feeds. However, plastics have poor thermal conductivity, so care must be taken to prevent the area being machined from getting too hot. Although plastics are much softer than metals, for example, they may contain abrasive particles or other materials such as glass fibers that can dull the machining tools. Using dull tools generates more heat, so preventative maintenance schedules must be observed to ensure tooling doesn’t become dull and thereby damaging to your plastic components.

Each type of plastic material has its own unique characteristics. Plastics that are hard and brittle are subject to chipping and cracking while being machined. Plastics that are softer are more affected by the stress placed on them by the tools and can be subject to warping. Similarly, overtightening the fixture holding the part being worked can result in damage or warping.

The bottom line is that it’s important to select the most appropriate tool geometries and speeds and feeds to obtain optimum performance with each type of plastic material being machined.

Tips and Tricks

As you can see, each machining process presents its own unique challenges. Determining the optimal tooling and speeds and feeds for all the tasks required to machine a part requires a vast amount of experience.

Here at HP Manufacturing, we’ve been working with both thermosets and thermoplastics since our company was founded in 1939. As a result, we have built a tremendous amount of expertise and an enviable reputation with respect to machining and finishing parts and creating sub-assemblies… everything that’s required to satisfy our customers’ exacting requirements.