Nylon machined products find extensive use in diverse industries. Applications can include products for the automotive sector, aerospace, the electrical and electronics industry and industrial machinery, commonly used for components such as gears, pulleys, bearings, rollers and the like.

Nylon offers exceptional strength and durability, becoming a material of choice due to several attractive properties:

- High Strength and Durability: Nylon is known for its exceptional strength and durability. It has a high tensile strength, making it suitable for applications that require robust and load-bearing components. Nylon’s toughness allows it to withstand mechanical stress, impact and abrasion.

- Excellent Chemical Resistance: Nylon exhibits good resistance to many chemicals, including oils, solvents, alkalis and weak acids. This property makes nylon suitable for applications that involve contact with chemicals or corrosive substances, such as in chemical processing equipment, automotive components, and machinery parts.

- Low Friction and Wear Resistance: Nylon has a low coefficient of friction, making it an excellent choice for applications where reduced friction and wear are important. It can be used for bearings, gears, conveyor belts and other applications that involve sliding or rotating components. The self-lubricating properties of some nylons also contribute to its wear resistance.

- Good Insulation Properties: Nylon is an excellent electrical insulator. It has a high dielectric strength, making it suitable for electrical components and applications. Nylon can be used for cable insulation, connectors, switches and other electrical parts where insulation and electrical properties are crucial.

- Lightweight: Nylon is a lightweight material. Its low density contributes to the overall weight reduction of the finished products without compromising strength and durability. This property is beneficial in automotive, aerospace and other industries where weight savings are important.

- Moldability and Versatility: Nylon can be easily machined into various shapes and sizes using different manufacturing processes. It offers design flexibility, allowing manufacturers to create complex and intricate parts. Nylon is available in different grades and formulations, offering a wide range of mechanical and thermal properties to meet specific application requirements.

- Moisture Resistance: Nylon has low water absorption, which helps retain its mechanical properties even in moist environments for products such as outdoor equipment, marine components and sports gear.

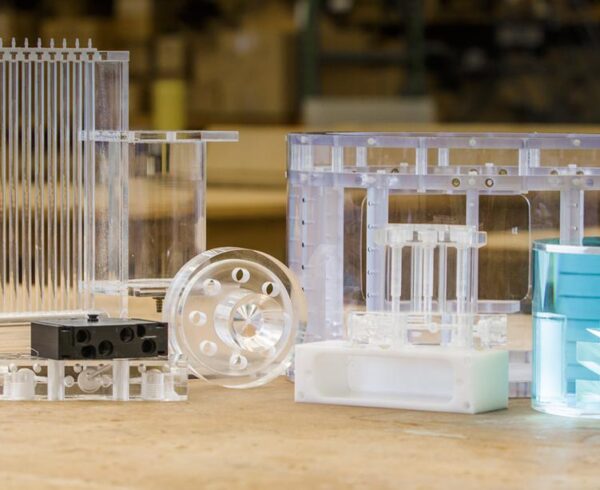

Nylon is available in various forms for machining and fabrication to cater to different manufacturing needs. Some of its most common forms:

- Sheets in different thicknesses, widths and lengths

- Tubes, available in various diameters and wall thicknesses

- Rods, in different diameters and lengths, which can be machined, drilled, turned or cut

- Films

While Nylon is a versatile material for CNC machining, at HP we’ve found that it does present some challenges that manufacturers need to be able to handle and manage. It takes an experienced team to effectively manage the challenges nylon presents for forming and machining.

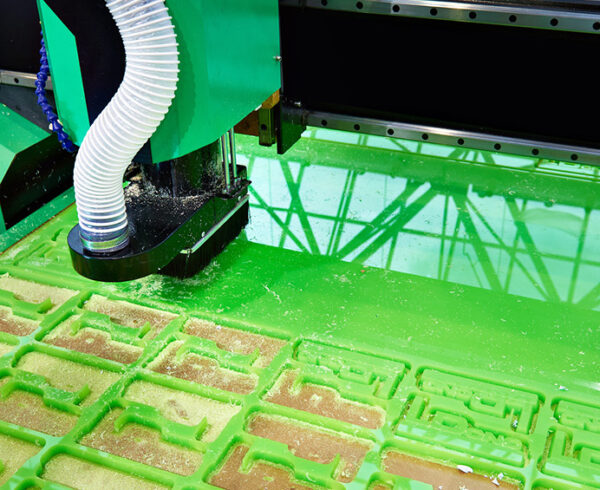

- High Heat Generation: Nylon has a relatively low melting point compared to some other engineering plastics. During CNC machining processes like milling or drilling, the heat generated by the cutting tools can cause localized melting or deformation of the nylon material. This can result in poor surface finish, dimensional inaccuracies, or even damage to the piece. Appropriate cooling techniques are employed to dissipate heat and maintain the integrity of the part.

- Low Thermal Conductivity: Nylon has low thermal conductivity, meaning it doesn’t dissipate heat quickly. The heat generated during CNC machining can accumulate in the piece, leading to increased softening or melting. Our teams at HP manage this by monitoring cutting speeds, feed rates and employing proper cooling methods to manage heat buildup.

- Stringing and Chip Control: This material can produce stringy chips or long, thin strands during CNC machining, especially when using high-speed cutting tools. These can interfere with the machining process and affect the quality of the finished part. We control chip formation to ensure smooth machining and to prevent tool damage.

- Workholding and Stability: Due to its relatively low rigidity and high coefficient of thermal expansion, Nylon can be prone to vibration and movement during CNC machining. This can result in poor dimensional accuracy and surface finish.

- Material Flexibility: Nylon is a soft and flexible material compared to metals or rigid plastics. This can pose challenges during CNC machining as the material may deform or deflect under cutting forces, leading to inaccuracies or poor surface finish. Our technicians know how to employ proper tool selection, feed rates and machining strategies to minimize these issues.

With decades of experience fabricating and machining high-performance plastic materials of all types, our technicians understand the challenges and know how to apply the proper machining techniques to overcome these challenges for a quality output. Contact HP to discuss your next project and whether Nylon is the ideal material for your design.