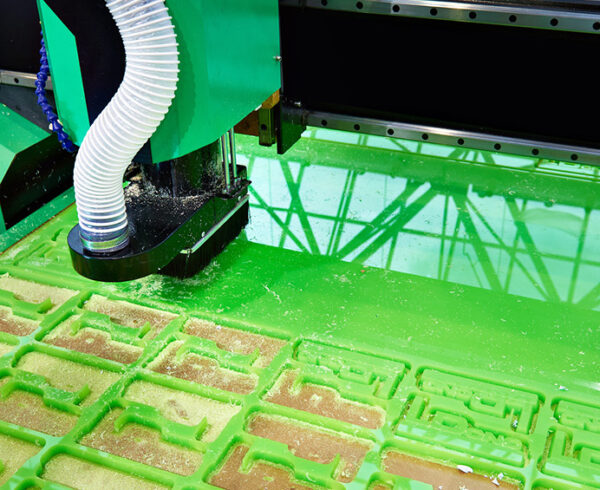

One highly effective way for companies to retain their competitive edge is by taking advantage of the most sophisticated technology available. One such technology that revolutionized manufacturing is a Computer Numerical Control (CNC) machine, which serves to automate machining and fabrication of complex parts. CNC machines offer a cost-effective means of manufacturing complex parts, reduce the potential for error, and improve quality and precision. CNC machines are available in 3-, 4-, and 5-axis varieties, each offering its own advantages and disadvantages, depending on the application. In this blog post, we will be discussing the differences between them to help determine which type of CNC machining will best suit your application.

What jobs does a CNC machine perform?

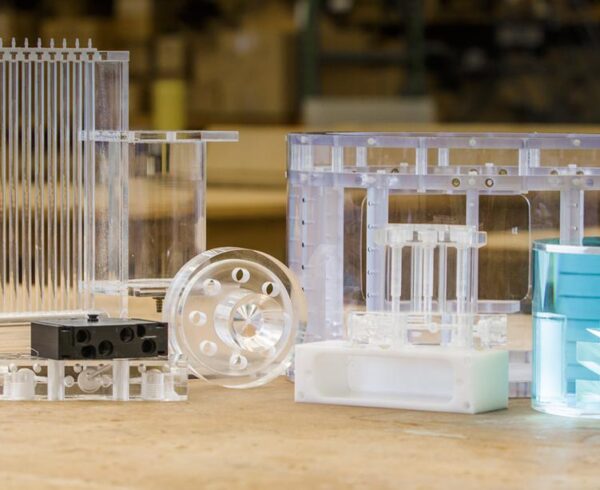

CNC machines are computer-controlled tools that cut materials like metal, wood, or plastic into various shapes or forms. They use a numerical code to establish a series of instructions that guide the machine to create precise shapes as experienced machinists oversee the programming and process. There are several types of CNC machines available, including 3-, 4-, and 5-axis machines. Each type has different features and capabilities.

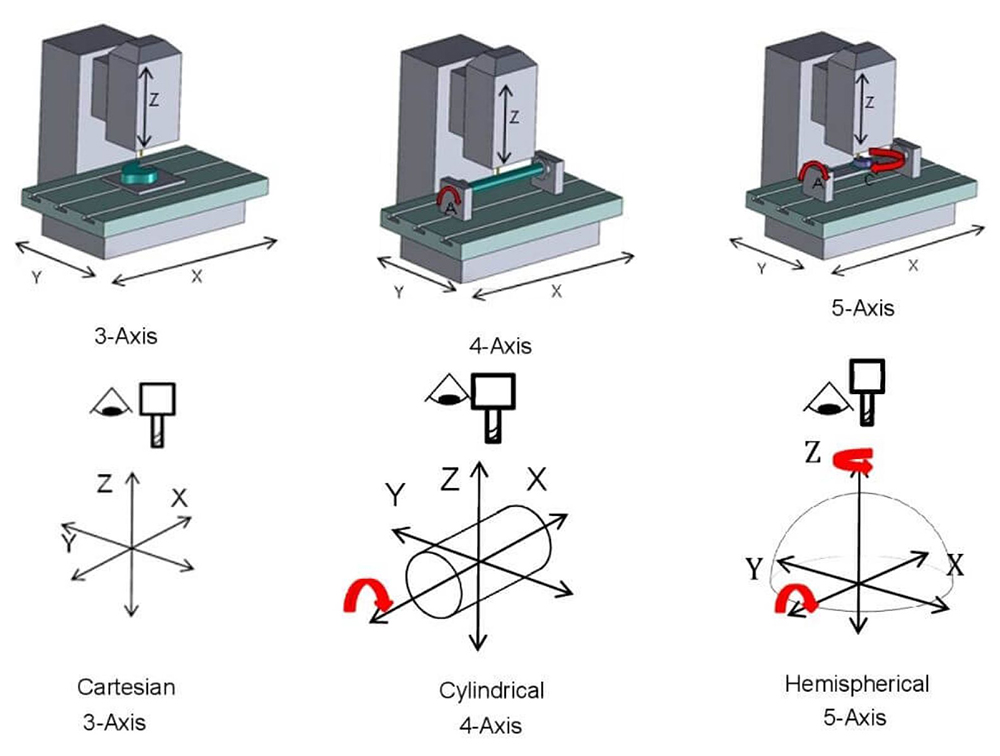

A 3-axis machine allows for three linear axes of movement: x, y, and z, as well as one rotational axis (A). This type of machine is commonly used for milling operations, such as drilling or boring holes into material. This type of machine has the most limited number of axes and limited precision when compared with more advanced machines that have more axes.

A 4-axis machine adds an additional rotational axis (B) to the x, y, z movements offered by the 3-axis machine. The additional axis allows for more complex machining operations, such as contouring or thread cutting on cylindrical parts. Additionally, this type of machine can be programmed to move all axes simultaneously or can be set up to perform multiple machining operations at once, reducing setup time between jobs.

Advantages of a 5-axis CNC machine

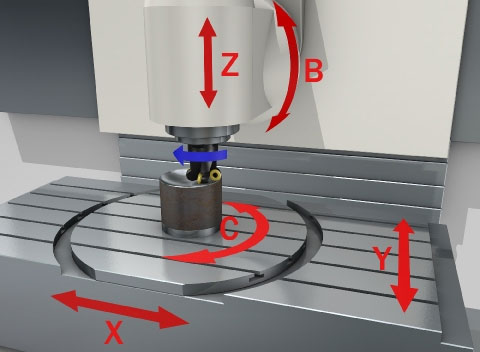

Unlocking the potential of CNC machines, the 5-axis machine is a highly sophisticated machining center that allows for unprecedented complexity and versatility. It allows intricate connections, curved surfaces, and three-dimensional shapes to be created with ultimate precision and a single setup.

A 5-axis machine adds yet another axis, a tilting axis (C), that enables even more complex machining operations compared to a 4-axis machine. It can, for example, sculpt curved surfaces or cutting threads in hard angles, while other types of CNC processes would not be able to conduct these operations due to limited range of movement/rotation. Additionally, the extra axes allow it to create these complex parts with tighter tolerances and fewer overall setup changes between jobs. This offers greater versatility, saves time, and increases efficiency.

Due to the high level of precision and tight tolerances it achieves, parts processed using 5-axis CNC machining can meet stringent specifications for industries such as medical instrumentation or aerospace, two of the industries served by HP Manufacturing. Other industry sectors we serve include wind or power generation and distribution, agriculture, food processing, electronics, and industrial/heavy equipment OEMs.

In summary, the 5-axis CNC machine, combined with our experienced, highly trained staff, offers the following advantages:

- Complexity — Completes parts with greater detail and different angles in a single pass, compared with multiple operations at different stages

- Single Setup — The complexity allowed by the five axes for complex geometries and sharp angles, in a single pass translates into a single set up and a completed part on a single machine, instead of needing to transfer parts to three, four, or more machines.

- Faster turnaround — The single setup and programming options eliminate the need for molds and tooling for quicker completion of complex jobs

- Greater accuracy — The number of axes contributes to greater accuracy while machining complex parts within tight tolerances

- Versatility — The number of axes creates possibilities for complex parts that would have been unimaginable 20 years ago

- Precision — The high level of precision drastically reduces the potential for error and improves quality and reliability

Look no further than HP Manufacturing for custom plastic fabrication and machining of the utmost quality. We have a fully equipped, 110,000-square-foot production facility. Our 5-axis CNC machines represents just one type of state-of-the-art machinery and advanced technologies we leverage to create, cut, and form intricate OEM components.

Fill out a contact form to discuss your next project with HP Manufacturing.