Fabricating products out of acrylics using processes like solvent welding (cementing), break forming, flame polishing, and drape forming requires a lot of expertise.

Fabricating products out of acrylics using processes like solvent welding (cementing), break forming, flame polishing, and drape forming requires a lot of expertise.

As experts in plastics and plastic fabrication, we often receive queries about different aspects of working in a variety of plastics materials. Take acrylic, for example. Many people are confused as to what acrylic is, the ways in which it can be formed, how it can be manipulated and fabricated, and what it can be used for, so let’s address these questions.

What is Acrylic?

Acrylic is a thermoplastic, which means that it becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

First synthesized in 1928 in the laboratories of the German chemical firm Röhm and Haas, the scientific name for acrylic is polymethylmethacrylate, or PMMA for short. These days, people often refer to acrylic using various trade names and brands, such as Acrylite, Astariglas, Crylux, Lucite, Optix, Perclax, Perspex, Plexiglas, and others.

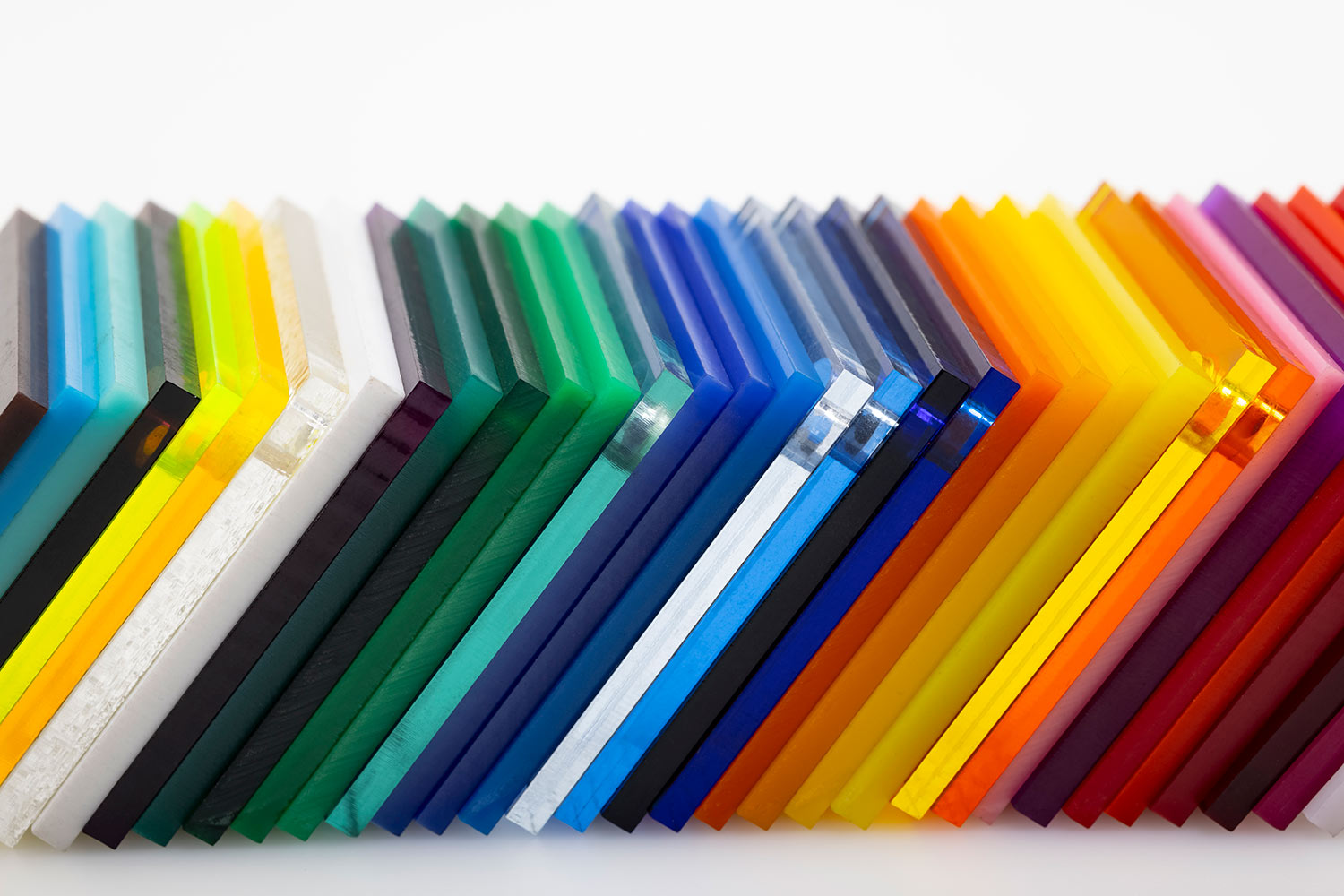

Is Acrylic Transparent, Translucent, or Opaque?

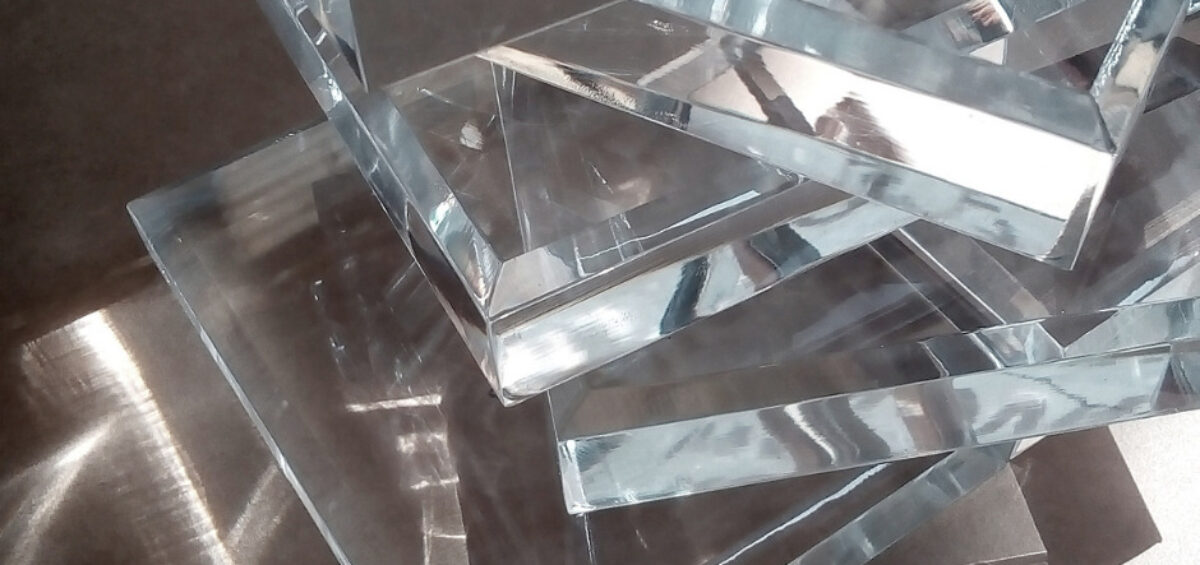

Yes! In fact, many sources start off by stating that acrylic is transparent, but this is only one possibility. In its natural state, acrylic is indeed transparent and exhibits glass-like qualities such as optical clarity and brilliance. However, by means of different additives, acrylic is available in a variety of colors (regular, pastel, fluorescent, iridescent), all of which may be offered in transparent, translucent, and opaque forms.

Acrylic also is available in metallic colors that are designed to emulate the look of natural metals, such as anodized aluminum, brushed aluminum, bronze, copper, and rose gold. Furthermore, acrylic is available with a variety of coatings, such as antimicrobial, mirrored, and scratch-resistant finishes.

What are the Properties of Acrylic?

As was previously noted, acrylic exhibits glass-like qualities such as optical clarity and brilliance. In addition to being lightweight, rigid, and extremely durable, acrylic has high impact resistance (10 times that of glass) and exceptional dimensional stability.

Its low water absorption, high resistance to ultraviolet (UV) light, excellent resistance to chemicals and contaminants, and the fact it will not corrode makes acrylic innately weatherable and inherently suitable for use in outdoor and other hostile environments.

What Can Acrylic be Used For?

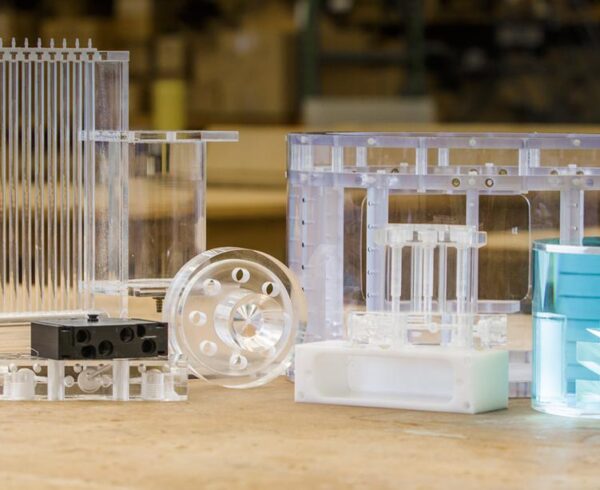

Acrylic finds use in a tremendous breadth of applications, from corneal transplants in cataract surgery to aquariums to windows in airplanes, skyscrapers, and even submarines.

Due to acrylic’s pleasing aesthetic qualities, a small sampling of commercial applications include cosmetic displays, top-of-counter (TOC) displays, other point-of-purchase (POP) displays, brochure holders, shelves and retail fixtures, frames and display cases, LED diffusing lighting panels and any other units that require forming and clarity.

How is Acrylic Formed and Presented?

Acrylic is available in a variety of shapes and sizes, including sheets ranging from 0.01” to 4” in thickness (or more for specialty applications) and up to 108” square, rods (round and square) from 0.06” to 6” in diameter, and tubes from 0.25” to 24” in diameter. There are also custom-sized options that could be considered and that would be available from a skilled acrylic fabricator such as HP Manufacturing.

The two main manufacturing methods are “extrusion” and “casting.” Extrusion is a continuous manufacturing process in which the acrylic is heated into a superhot liquid with the consistency of thick corn syrup and then forced through a nozzle where it becomes rigid as it is cooled by air. One aspect of this process is that the properties of the extruded acrylic are heterogeneous, which means they may vary depending on the direction of extrusion.

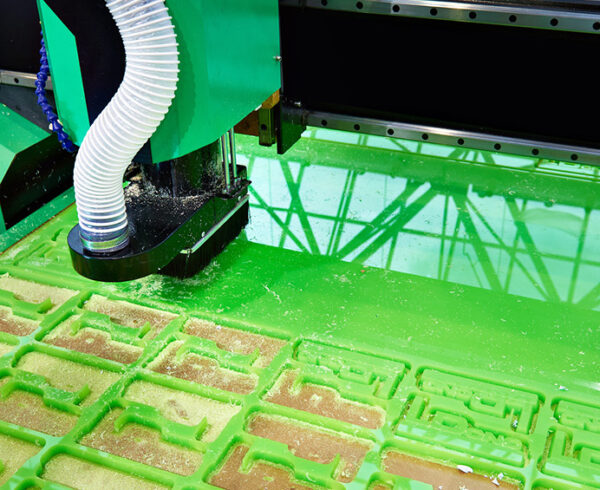

Casting also involves heating the acrylic into a superhot liquid. In this case, however, the liquid is poured into a cast or mold. Casting is more expensive and more labor intensive, but it results in more homogeneous products that are harder and sturdier than their extruded counterparts. In addition to working better with laser cutting, cast acrylic is more pliable and less likely to bend, chip or melt during fabrication.

There’s also a process called “continuous casting” in which a continuously extruded sheet of acrylic is extruded and air-cooled, thereby allowing sheets of any desired length to be created.

How is Acrylic Fabricated?

The term “fabrication” embraces multiple activities, including machining, assembly, and finishing. Machining is typically performed using computer numerical control (CNC) machines but may (more rarely) be performed by hand. All of the common machining operations may be employed, including cutting, turning, routing, milling, drilling and grinding (see also our blog Machining Plastics Tips and Tricks).

Laser cutting may be employed to achieve complex radius shapes, and additional processes may be used to manipulate the shape of the acrylic, including strip heating, break forming and drape forming. In the case of strip heating, the acrylic sheet is brought into proximity with a length of resistance wire (the “strip”). When current is passed through the resistance wire it heats up, reaching temperatures as high as 500°C, which causes the acrylic to soften, after which it can be bent into the desired angle.

Break forming, which also is known as break bending, uses a similar mechanism to that employed for bending large sheets of metal. In this case, however, the edge over which the acrylic sheet is to be bent is heated, thereby causing it to soften before the bending takes place.

Drape forming is a highly specialized process that is used when sophisticated multidimensional curves or shapes are required. In this case, the acrylic sheet is first heated to soften it and make it pliable, after which it is pressed into or over the desired form, possibly assisted by gravity and/or the use of a vacuum.

Following machining, multiple pieces of acrylic can be assembled using a cyanoacrylate cement (commonly known as superglue), with heat (welding), or by using chlorinated solvents (solvent welding) to dissolve the plastic at the joint, which then fuses and sets, resulting in an almost invisible joint that is stronger than the surrounding material.

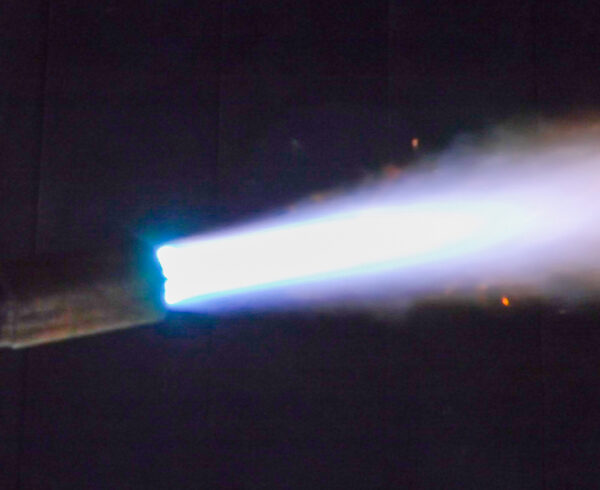

Finally, finishing may include buffing (either by hand or using automated machines) to achieve a glass-like finish. Alternatively, a process called “flame polishing” (also known as “fire polishing”) achieves much the same effect using a flame, which causes the surface of the material to briefly melt allowing surface tension to smooth the surface. Operator skill is critical with this method but, when done properly, flame polishing produces the clearest acrylic finish.

How Can HP Help You?

Here at HP Manufacturing, we’ve been working with plastics since our company was founded in 1939. In the case of acrylics, we warehouse an exceptional range of shapes, sizes, and colors of extruded, cast, and continuous cast materials.

Of particular importance to our customers is that we partner with companies who provide quality materials whose color is consistent throughout and that will cement well, both properties that are not always true of cheaper materials from many other sources such as Asia.

Over the decades, we have built a tremendous amount of expertise and an enviable reputation with respect to machining and finishing acrylic parts and creating sub-assemblies… everything that’s required to satisfy our customers’ exacting requirements while meeting tolerances others find difficult to achieve.

Manufacturers, please click here to request a quote.

Consumers, please click here to request a quote.