At HP, we understand the importance of delivering components that are machined to the highest tolerance with the utmost precision. HP Manufacturing has over 81 years in the industry and has perfected the CNC machining process. Through our continued investment in the latest CNC technology, combined with our team of experts, we have the capability to deliver a superior finished product.

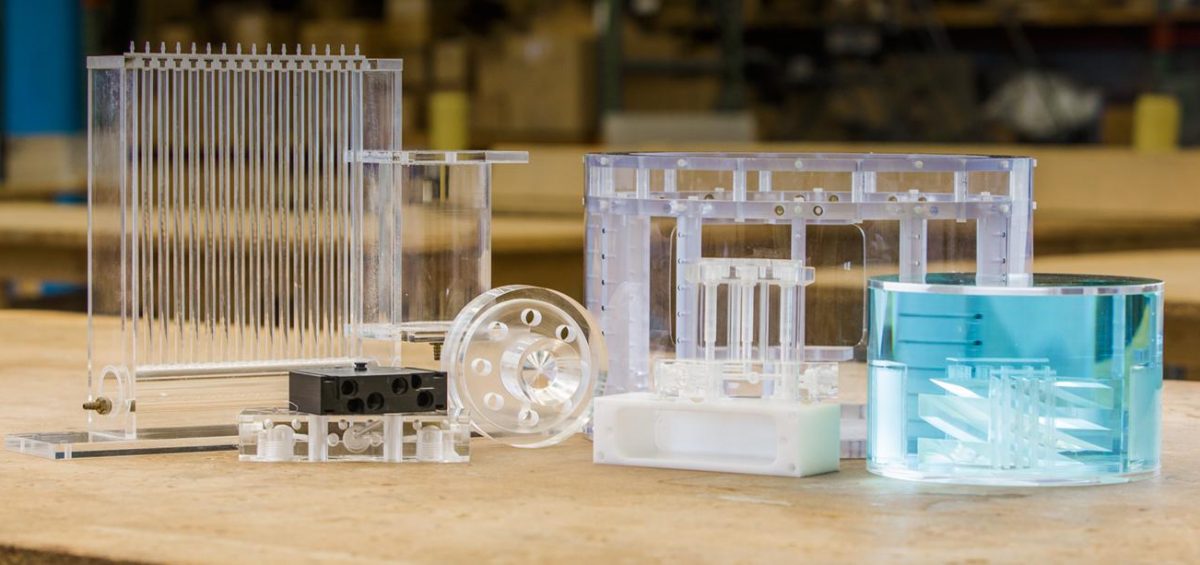

We work with a wide variety of industries, including healthcare, medical imaging, aviation, transportation, and retail, to manufacture OEM custom plastic parts compliant with required industry standards and regulations. We can leverage our CNC machining expertise to manufacture custom plastic components and assemblies for your specific industrial application.

While there are numerous ways to manufacture custom plastic products, such as injection molding and other molding methods; We specialize in CNC machining and plastic fabrication to offer a cost-effective and precise solution.

WHAT IS CNC PLASTIC MACHINING?

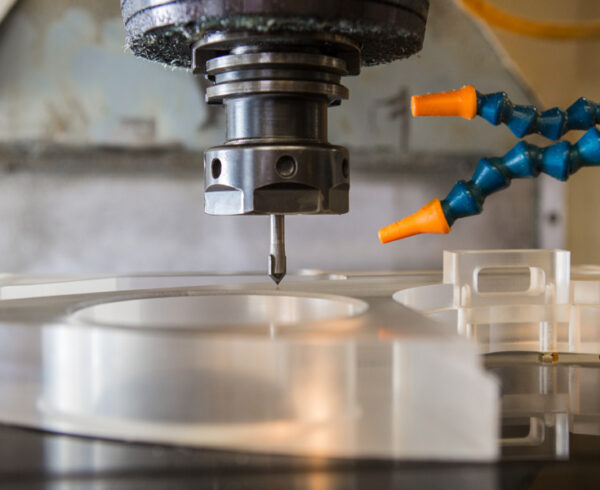

CNC Plastic machining is a manufacturing process that involves using high-speed tools to remove material from raw sheet materials. CNC stands for Computer Numerical Control because it uses a computer to drive the machine. The computers guide and automate processes such as plastic milling, turning, and routing.

- CNC Milling: Milling is a subtractive manufacturing process that involves cutting parts from a block of raw plastic. The cutting tool comes in a variety of shapes and can move in three dimensions. The raw material sits on a platform that also moves in numerous orientations for complex angles.

- CNC Routing: Routers are essential in the fabrication process for creating intricate designs around tight tolerances. Using a spindle, the machine cuts along three and sometimes five axes.

- CNC Turning: Also known as CNC lathes, this machine helps create cylindrical parts. By mounting and spinning the plastic materials, the machine can cut curved and tight angles.

TYPES OF PLASTICS THAT CAN BE MACHINED

Pick from over 50 common materials that meet your application requirements. Our wide range of innovative plastics includes:

- Acrylonitrile Butadiene Styrene (ABS): A popular choice for electrical applications, ABS is a thermoplastic polymer known for its strength, high heat resistance, and affordability.

- Acetal Copolymer: Acetal is often used to manufacture valve parts, food processing and packaging parts, and more. Characteristics of acetal include low friction, strong, stiff, and good chemical resistance.

- Polytetrafluoroethylene (PTFE): Also known as Teflon, PTFE is a high-performance plastic with impressive heat, light, and chemical resistance. This is most commonly applied to non-stick cookware but is also prevalent in industrial parts with the need for strength and resistant capabilities.

Not sure which material is suitable for your specific application?

WHY HP?

WE ARE EXPERIENCED

HP Manufacturing has spent over 81 years perfecting the CNC machining process. We’ve invested in the latest CNC technology, which allows us to deliver a superior product with precision.

WE ARE FULL-SERVICE

We have the equipment and experience to help you in every step of the process, from idea to prototype to a final product. We are a full-service plastic fabrication company.

WE KNOW QUALITY

We understand that customers need parts or assemblies that are of the highest quality. Whether you need machining, forming, laser cutting, or a combination of these processes, you can expect our absolute best.